Bosco produces huge volumes on a daily basis. In addition to meeting all domestic requirements, the company is all set to increase its presence in the global markets.

Various footwear categories:-

Bosco has ventured into home, casual, sports and school wear. Currently, it has 4 footwear categories, namely, Sandals, Jogger, Leather, Joggers, and Schoolmate. P U, TPR, PHYLON, PVC, EVA, RUBBER It is one of the few companies that maintain consistent production activity in such a varied range of footwear.

Productions & Operation:-

The company has one of the strongest infrastructure in rubber footwear in India, and the best in the state of Rajasthan .Company is using the best of the technology of India and Abroad. Several imported machinery is used to maximized the productivity tools to optimize the value addition. The Quality control system ,motivated and dedicated team has made “Bosco” a strong brand. Research & development in new designs, chemicals, machinery, and many innovations is part of the daily routine .Our Lab is one amongst the best in India.

Performance:-

With the commitment to quality product, efficient value addition, penchant for customer service, satisfaction & relation, passion for innovation, company has grown a leader in Rubber footwear.

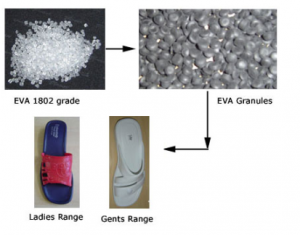

The manufacturing process of these eva injection moulded slippers is completed in four steps:

- Preparation of EVA Compound

- Injection for granules

- Injection of Straps and uppers

- Fitting & Packing

The manufacturing process of EVA injection moulded slippers can be summarized as under :-

Preparation of EVA Compound:- EVA compound is prepared by mixing EVA 1802 grade with other ingredients like colours, curing agents, blowing agent in kneader. This compound from Kneader is then passed through extruder, and finally through granulator to get EVA compound in the form of granules. These granules are then passed through water chamber for cooling and removing dust and are passed through numbers of cyclones for drying.

Injection of granules:- The granules are injected into sole mould placed on the presses of fully automatic computerized EVA injection machine. After curing of sole, presses open up automatically and an expanded sole comes out from Injection machine. The time, temperature and volume is maintained by computer, as per requirements.

Injection of straps and uppers:- PVC compound granules are injected to the straps mould through horizontal PVC injection machine.

Fitting & Packing:- Straps obtained from horizontal machine are inserted Into EVA sole. After quality checking, slippers are packed in C. B. boxes and finally to cartoon.

The PU Sole footwear manufacturing process consist of three steps:

- Manufacturing of Synthetic Leather uppers and straps.

- Pouring of PU Liquid into moulds of shoes by pouring machine.

- Finishing & packing.

Manufacture of Uppers :-

To manufacture uppers from synthetic leather sheet, the Upper sheet is pasted with PU liner cloth by the lamination machine. Required uppers are then cut from the pasted sheet by putting on platform of upper cutting hydraulic machine and then placing knife on the sheet. The cut uppers then send for stitching by industrial sewing machines. After stitching, eyelets are inserted into the uppers by eyeleting machine and insoles (sox) are stitched by string lasting machine.

Pouring of PU liquid into moulds :-

In this process , first of all ready uppers are lasted. On the last of Shoes mould manually and then moulds are closed. These closed moulds are then kept on the 62 stations conveyer, which moves in anticlock wise direction. In this way the moulds keep moving along with conveyer. The conveyer stops for a few minutes under the arms of pouring machines where the PU Liquid (mixture of Poly isocyanate and polylol) is poured into hot mould by the nozzle fitted into the tubes carrying PU Liquid which comes through pump from the containers of Poly isocyanate and polylol.

The whole arrangement is fixed on the stand of the machine (arms). Before pouring the liquid into mould, moulds are cleaned by MCL Liquid and then mould-realizing agent is applied inside the mould, the moulds are heated by passing though the hot chamber, which is fitted, on conveyers. The setting of PU liquid in hot moulds starts gradually and after setting of PU, moulds are opened manually. Shoes are then removed from the mould and another upper is lasted on the last of mould for PU casting. The computer of the machine controls the volume of PU liquid, pouring time, time period and mould temperature.

Finishing & packing:-

After casting PU sole, shoes are shifted for checking, & trimming and then printed sponge insole is inserted into the shoes. The finished shoes are packed into Corrugated Boxes and finally into cartoon.

The process flowchart of manufacturing PU Footwear can be depicted as under.

Company is marketing its product under the registered trade “Bosco” which has become synonym for a good quality footwear. At Bosco, customer service & satisfaction is the prime motto. The department is managed professionally, and every customer is served well here. At present company has a strong marketing network all over India. The department is prompt and best of the services are available to all our customers. The department is well equipped with all the latest communication systems like emails, fax, etc.

Keeping pace with the time company has launched a new brand “Best EVA” of the plastic footwear, and slowly and steadily entering the market

With the team of 200+ sincere distributors we serve the states of Rajasthan, Gujrat, MP CG, Hariyana And Others.

Vision

To Create Value for the world.

Mission

To Create & deliver higher value for money service to our consumers or users

To serve & satisfy of customers, and all associates

To fulfill the needs of our people,

To inculcate values, to develop a responsible society

The Right Socks

When trying on shoes, make sure you are wearing the appropriate socks. For instance, if you are trying on boots

The Right Time

The best time to try on shoes is usually at the end of the day, when your feet are most swollen. The point of waiting until the end of the day is to make sure that the footwear can fit you at your widest– kind of a “worst case scenario” check.

The Right Foot

The first shoe you try on should be for your larger foot. For most people, their larger foot is the opposite from the hand they write with. For example, if you’re right handed, your left foot might be bigger. Always fit the pair of shoes to this foot.

The First Step

Stand up with your shoes on. Walk around. You should be able to wiggle your toes in the front of the shoe. For most footwear, your toes will be able to touch the top of the shoe, but there should be 3/8″ to 1/2″ of space between your longest toe and the end of the shoe. Different styles can sometimes dictate a different amount of space at the end of the shoe for example ” pointed toe” style.

The Right Shoe

Don’t buy shoes that are too tight. If you’re at the point where you’re hoping they will stretch to be comfortable, they probably won’t. It’s true that soft leather and suede give slightly, moulding to your foot, but they will not dramatically increase in width or length. There’s a difference between a “snug”, comfortable fit and a “tight”, uncomfortable fit. A few laps in the store should help you decide how you feel.

MAINTAINING YOUR SHOES & LUGGAGE

- Shoes are an expensive investment, but with care they can last a lifetime.

- Always polish shoes after use. Polish nourishes the leather from cracking and drying out.

- Place wood shoe trees in the shoes after use, thus retaining the shape and removing moisture. Shoes should not be a tight Fit, just a sufficient tension to hold on shoes without stretching at top of heel

- Try not to wear the same pair of shoes on consecutive days. The life of your shoes can be greatly extended if they are rested between use.

- If you wear suede or unbuck shoes, brush them regularly.

- The careful application of a Scotch guard™ spray will repel most stains (but not grease and oil).

- Do not allow soles to become too thin as this may damage other parts of the shoes, such as the welts and uppers

- Always use a good shoe or boot horn; this will prevent irreparable damage to the back stiffening of the shoes.

- Do not dry damp shoes on direct heat.